How to choose the right sliding mitre saw

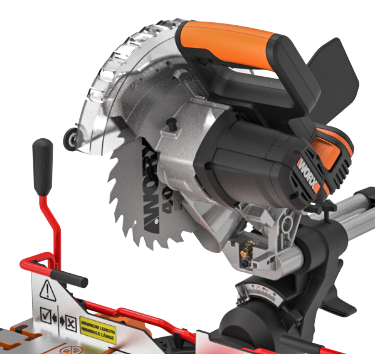

A mitre saw is a circular saw that is fixed to a stationary base for accurate cuts. Mitre saws are mainly used for crosscuts both at 90° and angle cuts for crown mouldings, picture frames and many types of architrave and mouldings that are required to fit into corners and around door frames etc. The workpiece is stabilized by resting it against a backstop called a fence. While the most common angle is making complementary 45º angle cuts for right angle joints, a whole range of angles can be achieved by pivoting the blade arm horizontally. Many mitre saws are corded and must be plugged into an electrical outlet, but cordless mitre saws can run on a rechargeable battery. While mitre saws are most often used on wood, they can also be used on a wide variety of materials if you choose a blade designed for the specific material of the project, whether it’s metal, plastic, masonry, laminate flooring, and so on. Because of the types of projects, they are used for, mitre saws tend to be smaller and fairly portable compared to other stationary saws.

How to choose the right sliding mitre saw

A mitre saw is a circular saw that is fixed to a stationary base for accurate cuts. Mitre saws are mainly used for crosscuts both at 90° and angle cuts for crown mouldings, picture frames and many types of architrave and mouldings that are required to fit into corners and around door frames etc. The workpiece is stabilized by resting it against a backstop called a fence. While the most common angle is making complementary 45º angle cuts for right angle joints, a whole range of angles can be achieved by pivoting the blade arm horizontally. Many mitre saws are corded and must be plugged into an electrical outlet, but cordless mitre saws can run on a rechargeable battery. While mitre saws are most often used on wood, they can also be used on a wide variety of materials if you choose a blade designed for the specific material of the project, whether it’s metal, plastic, masonry, laminate flooring, and so on. Because of the types of projects, they are used for, mitre saws tend to be smaller and fairly portable compared to other stationary saws.

How do they work?

As any circular saw, a round, toothed saw blade is spun at high speeds by a motor. The difference is that the blade is held on an arm that can pivot in certain directions to achieve different kinds of cuts to a workpiece. Standard mitre saws are limited to a range of mitre cuts. Compound mitre saws can make compound cuts, meaning both mitre and bevel cuts, but can only make bevel cuts in one direction. These are also called “single-bevel” mitre saws. Dual compound mitre saws make compound cuts that include bevel cuts in both directions (left and right), allowing for the maximum range of angles possible. These saws are also referred to as “dual-bevel” mitre saws. Finally, a sliding mitre saw has a set of rails that allow the blade and motor assembly to move independent of the base. The sliding feature increases the size of workpiece that the blade can cut.

Explore our sliding mitre saw

Did you know - why a sliding miter saw is better?

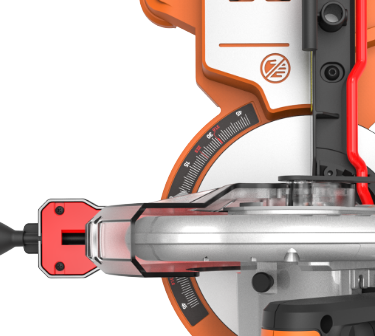

Without slide functionality, a mitre saw’s crosscut capacity is limited to slightly less than the saw blade’s diameter (because the arbor gets in the way). A sliding mitre saw increases the saw’s crosscut capacity up to 50% more than the saw blade’s diameter. This allows for a greater variety of cuts with a smaller less expensive blade and a more compact saw.

Did you know - why a sliding miter saw is better?

Without slide functionality, a mitre saw’s crosscut capacity is limited to slightly less than the saw blade’s diameter (because the arbor gets in the way). A sliding mitre saw increases the saw’s crosscut capacity up to 50% more than the saw blade’s diameter. This allows for a greater variety of cuts with a smaller less expensive blade and a more compact saw.

Size matters

The size of the circular saw blade, diameter measured in mm, drives the max crosscut capacity of a mitre saw, and the depth of cut that is possible. The largest common size of a mitre saw blade is 300 mm, making the max crosscut capacity just under that as the arbor gets in the way of reaching the exact measurement, and this size of blade often allows a vertical depth of cut of 100 mm or more. The next most common size down is a 250 mm mitre saw blade. There are then a variety of blade sizes smaller than 210 mm and 216 mm. Remember that mitre saws are primarily intended for making angled cuts in molding and trim, which is why most DIYers have no need for a 300 mm blade.

Worx Advantage

Worx Advantage

Worx Advantage: The Nitro 20 V PowerShare cordless sliding compound mitre sawWorx was the first to offer a truly portable, 20 V bench-top mitre saw as part of its Nitro family of tools that brings pro-grade performance and results to any serious DIYer. And it’s packed with all kinds of useful features and specifications. Aluminum frame construction has this mitre saw weighing in at only 9.5 kg. That’s less than half the weight of a conventional 250 mm mitre saw. An innovative workpiece holding clamping system secures the workpiece on both sides while keeping hands clear of the blade. A two-part adjustable fence system allows for taller materials, offering a max cutting width capacity is 209 mm at 90° and 146 mm at 45º.

Features for accuracy and precision

Mitre saws include many features to help achieve great accuracy and precision in cuts. While a whole range of angles is possible with most mitre saws, most projects only require a few of the most common angles. Some brands and models of mitre saws include “detents”, which means the saw will click into place for those common angles. A lock-down feature allows the motor assembly to be locked down to ensure the selected angle remains tight. Cutline visibility is another important feature, which may be enhanced with a laser blade guide or a LED light-assisted shadow line for better cutting accuracy.

Features for convenience and safety

Additional features that add convenience and enhance the safe operation of a mitre saw can include a dust port to which a collection bag or vacuum can be attached to remove as much sawdust as possible while operating the saw. Every mitre saw should have a blade guard, but it should be one that still provides as much visibility of the cutline mark as possible, and this is something that can vary widely from brand to brand and model to model. Most mitre saws do not have any built-in features for holding a workpiece in place, which means placing one hand directly on the workpiece to hold it in place while the other hand maneuvers the saw. This is a dangerous arrangement for beginners. Look for brands and models that have a workpiece holding feature that automatically keeps your hands well out of the saw-blade range.

Features for convenience and safety

Additional features that add convenience and enhance the safe operation of a mitre saw can include a dust port to which a collection bag or vacuum can be attached to remove as much sawdust as possible while operating the saw. Every mitre saw should have a blade guard, but it should be one that still provides as much visibility of the cutline mark as possible, and this is something that can vary widely from brand to brand and model to model. Most mitre saws do not have any built-in features for holding a workpiece in place, which means placing one hand directly on the workpiece to hold it in place while the other hand maneuvers the saw. This is a dangerous arrangement for beginners. Look for brands and models that have a workpiece holding feature that automatically keeps your hands well out of the saw-blade range.

Did you know - how an electric blade brake works?

After completing a cut with a mitre saw, releasing the trigger should result in the blade completely stopping its spinning within a few seconds. How is this accomplished? In the case of a mitre saw (and many other power saws) it’s an electric brake that stops the blade. What happens is that releasing the trigger reverses the flow of electricity, essentially putting the motor into reverse until the blade stops spinning. This is an essential safety feature as a malfunctioning break could leave the blade spinning for a minute or more, which is unsafe.

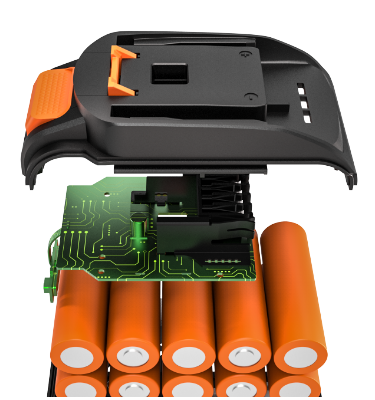

Better batteries to get the job done.

Most power tool battery packs may look the same but what’s on the inside can make a world of difference. Today’s high-performance battery packs for cordless power tools integrate newer cutting-edge designs to ensure that the batteries stay protected from impacts, water and electronic failure. Heat is the #1 enemy of long battery life. Dynamic cooling technologies allow for faster charging and extend the life of any battery pack.

Worx Advantage

Worx Advantage

The Worx 20 V PowerShare PRO batteriesWith better performance and longer run times than traditional cordless tools, Worx Powershare PRO™ batteries employ advanced engineering & cutting-edge tech for superior efficiency, so you'll get more done on every charge. Each Worx PowerShare Pro battery has integrated Intelligent battery management, innovative cell cooling technology and 360 degree cell protection for longer life and exceptional durability.

Olfactory memory

Igor gets his raw material from the woods all around his workshop and turns it into pieces that are appreciated across Europe.

“I grew up in the woods. I spent most of my youth hiding behind, climbing on, playing around trees. When I got back home at night, my hands were covered with sap, and that small is now forever stuck in my memories. Nowadays, I feel the same kind of emotion every time I start working on a log.”

“I grew up in the woods. I spent most of my youth hiding behind, climbing on, playing around trees. When I got back home at night, my hands were covered with sap, and that small is now forever stuck in my memories. Nowadays, I feel the same kind of emotion every time I start working on a log.”

Olfactory memory

Igor gets his raw material from the woods all around his workshop and turns it into pieces that are appreciated across Europe.

“I grew up in the woods. I spent most of my youth hiding behind, climbing on, playing around trees. When I got back home at night, my hands were covered with sap, and that small is now forever stuck in my memories. Nowadays, I feel the same kind of emotion every time I start working on a log.”

“I grew up in the woods. I spent most of my youth hiding behind, climbing on, playing around trees. When I got back home at night, my hands were covered with sap, and that small is now forever stuck in my memories. Nowadays, I feel the same kind of emotion every time I start working on a log.”

Same battery, expandable power

Worx PowerShare is a unique 20 V modular system that allows you to combine the same battery to multiply voltage to 40 V and even 80 V. PowerShare batteries are available in a choice of capacities so that you can choose what you need.

Cutting capacity up to 200mm with 70mm thick lumber

Cordless Sliding Mitre Saw NITRO 220mm 20V - Tool Only - WX845.9

Explore our sliding mitre saw

If you spend more time in your shed than your living room, you’re probably wondering what can we possibly teach you about tools that you don’t already know, right? Challenge accepted.